Do you know what different colors represent on the circuit board

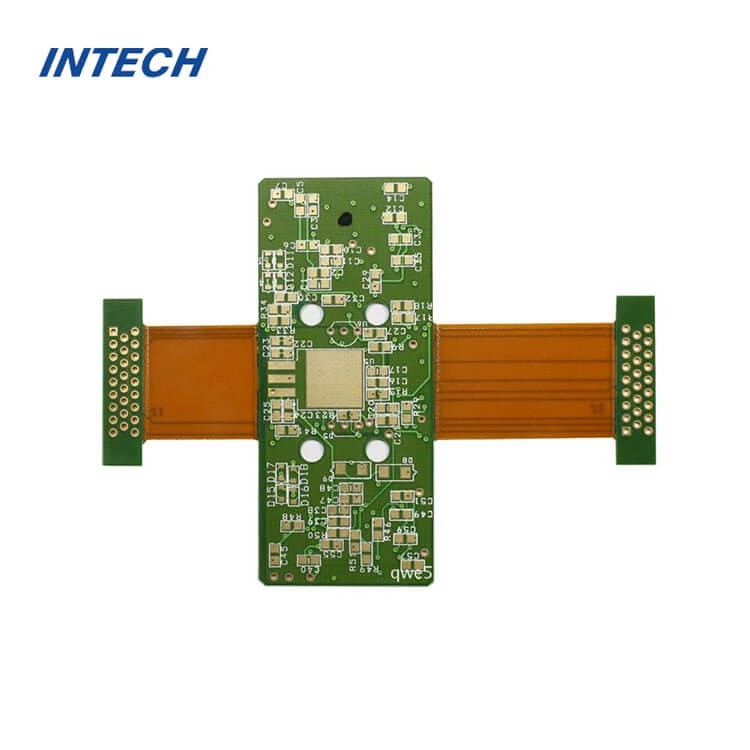

As the mother of electronic components, circuit board plays an important role in electronic applications. According to different design principles, circuit boards can be divided into single panel, multilayer board, soft board, hard board, soft-hard board and so on.After that, pcb assembly manufacturer Not afraid of the future, dare to fight and fight, and won applause again and again in the market. https://intechcircuit.com/

At present, the common PCB colors on the market are green, black, blue, yellow, purple, red and brown, and white and pink PCBs have appeared recently.

So, why do PCB boards have different colors? Have you found that most of the circuit boards are green, but other colors are rare? Why? Next, Shenzhen Lianxiaobian will give you a wave of knowledge about circuit boards ~

Why do PCBs have different colors?

In the production process of PCB, the final surface of copper layer is smooth and unprotected, whether by additive process or reduction method. Although the chemical properties of copper are not as easy to oxidize as pure copper of aluminum, iron and magnesium in contact with oxygen in water, the thickness of copper layer in PCB circuit board is very thin, and the oxidized copper will become a poor conductor of electricity, which will greatly damage the electrical performance of the whole PCB. In order to prevent copper oxidation, separate the soldered part from the non-soldered part of PCB and protect the surface of PCB, the design engineer will apply a special coating on the surface of PCB to form a protective layer with a certain thickness to block the contact between copper and air. This coating is called solder resist and the material used is solder resist paint. In order to facilitate maintenance and manufacturing, PCB usually needs to print small text on the board. Therefore, engineers added various colors to the solder resist paint, and finally formed a “colorful” circuit board.

Why are green inks widely used?

The color of solder resist mainly depends on the color of solder resist ink. Green ink is the most widely used and the cheapest in the market. In fact, the solder resist ink on the market is not limited to one kind of green, and there are many colors such as red, blue, purple, black and yellow, but green is the most common one. The main reason is that the use of green solder resist ink has the following advantages: it is convenient for optical positioning correction.

The manufacturing process of the circuit board itself includes STM welding process, and this process needs to be tinned and finally verified by AOI. These processes need to be calibrated by optical positioning, and the green background color has a better recognition effect for the instrument. In the yellow room, the visual effect is better. The whole PCB product has to go through the processes of board making and SMT in the production process. Usually, when the circuit board is used in the production and processing of electronic products, there will be some processes that need to pass through the yellow room. According to the optical law, the green circuit board has a better visual effect in the yellow room, and it is easier to check the production of electronic products.

It is beneficial for workers to observe the circuit board.

At present, due to the production process and other problems, the quality inspection process of many lines still depends on the naked eye observation and identification of workers (of course, flying needle testing technology is mostly used at present). It is very tiring to keep staring at the board under strong light. Using green as the background color of circuit board can reduce the damage of strong light to workers’ eyes, so most manufacturers in the market use green PCB at present.

Environmental protection and low cost.

Because the circuit board needs to be recycled at high temperature when it is discarded, and the green solder resist ink will not release toxic gases, recycling is more environmentally friendly. Thanks to the above advantages, the adoption rate of green solder resist ink is the highest and the production process is the most mature. Therefore, the cost of using green solder resist ink to produce circuit boards is also lower.